Equipment Features

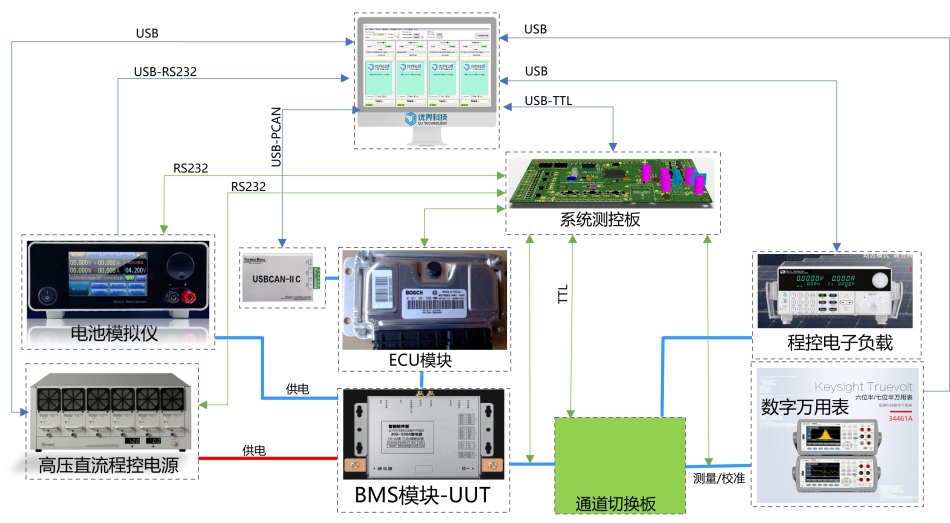

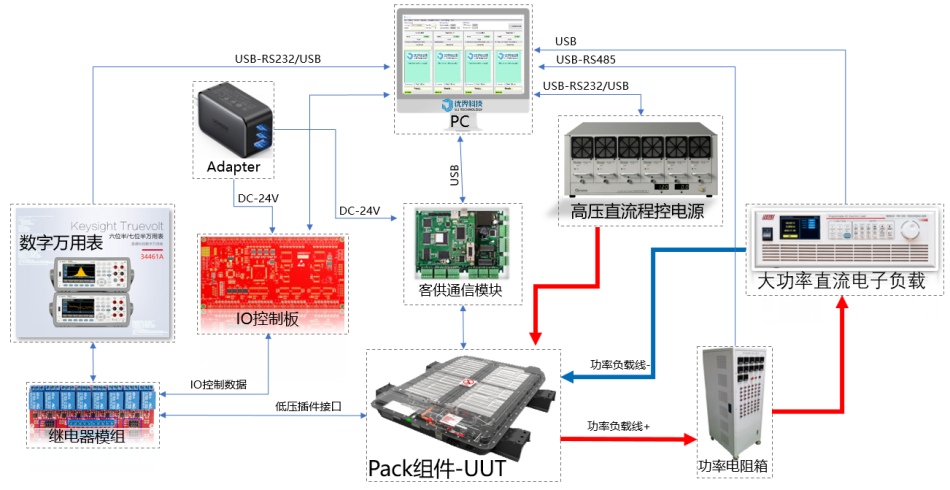

1. The core solution for BMB/BMS testing uses power resistors, electronic loads, high-power contactors, CAN communication, and programmable power supplies to complete rapid function testing (communication function / charging and discharging function) of the tested module.

2. It adopts a safety control system meeting the safety specification level of main engine factories, with separate test cabinets and test fixtures for flexible layout / asset reuse.

Function Introduction

| Main Module | Function Description |

|---|---|

Multi-channel High-precision Multimeter | BMS cell voltage, BMS cell temperature, total voltage accuracy, etc. |

CAN Communication Module | Communication testing, data reading, data writing, and SOC calibration function testing of the tested module |

High-precision Voltage Divider | Provide high-precision external pressure for the module under test. |

High-voltage Programmable Power Supply | Simulate the charging and discharging function, fast charging function, OBC slow charging function, etc. of the tested module |

Main Measurement and Control Module | Function testing of overcurrent, overvoltage, overcharge, overdischarge, system reset, wake-up, overvoltage protection time, overcurrent protection time, overcharge protection time, overdischarge protection time, etc. |

High-voltage Tester | Insulation resistance test, AC and DC withstand voltage test, |

AC and DC Internal Resistance Test | Measure the AC internal resistance and DC internal resistance of the battery Pack |

General Software Testing Platform | Communication testing, communication of each functional module, data interaction [reading/writing], test result display, data storage, etc. |

—————————————————————————————————————————————————————————————————————————————————————

Hello, due to the confidentiality agreements signed for the detailed technical information of some commercial cases, it cannot be displayed online! If you need to obtain a customized solution, please contact us via mobile phone & WeChat: 181-2451-5629