Semiconductor Industry Solutions

Mini LED Chip Displacement Machine

◆ The testing machine classified Mini LED chips (Unpackaged semi-finished products) according to its photoelectric parameters & cosmetic inspection results.

◆ Then, the sorting machine equipment will bond different levels of classification to different Bin carrying trays;

◆ The sorting process is an indispensable process in the LED chip production process;

◆ The unit operation time is 56ms, and the hourly production capacity is up to 50K pcs

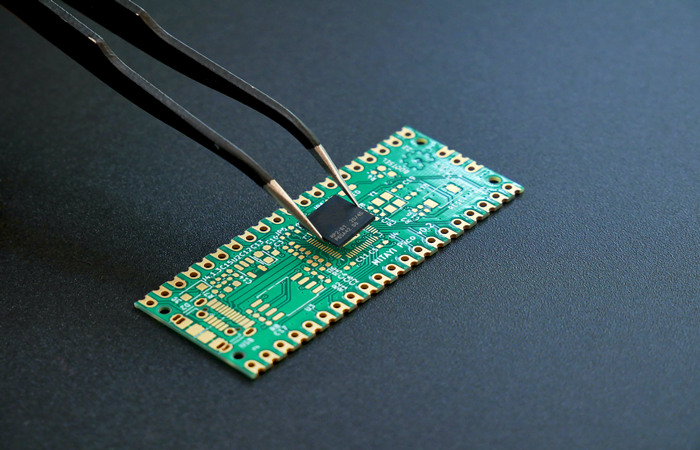

IC Chip Testing And Displacement Machine

◆ The semiconductor testing and sorting machine is used to test the electrical characteristics of the packaged chips in various environments, and then divide them into different grades and classify them according to their performance.;

◆ The whole machine adopts Yougen ultra-high-speed motion control technology, and the bus transmission is fast and reliable;

◆ Can provide software and hardware algorithm customization, IC and module system-level test solutions;

◆ Widely used in SOC/MCU, FLASH, EEPROM, Logic, CPLD/FPGA, CIS fingerprint chip, PMIC, PA, RF switch, filter and other semiconductor wafer, device testing and module system level testing

Thermo Stream System

◆ The testing machine outputs programmable high and low temperature airflow in the sealed cavity, and performs reliability tests on components such as temperature shock and failure analysis.;

◆ Efficient heating and cooling:-50°C~+125°C,+125°C~-50°C The temperature conversion is achieved within 10 seconds;

◆ Precise control: temperature control accuracy ±1°C, temperature resolution 0.1°C, temperature overshoot less than 2°C;

◆ Flash memory Flash/EMMC PCB, IC devices, MCM, small module components, optical communication (such as transceiver Transceiver high and low temperature test, SFP optical module high and low temperature test, etc.