Equipment Highlights

High speed and efficiency: 4-site or 8-site options available, maximum UPH up to 11,000/H;

Stable and reliable: Entire machine uses EtherCAT bus control system for stable and reliable communication

• Flexible expansion: Optional high-temperature, CCD and other functional modules available

Self-developed software: Various functions can be customized according to customer requirements

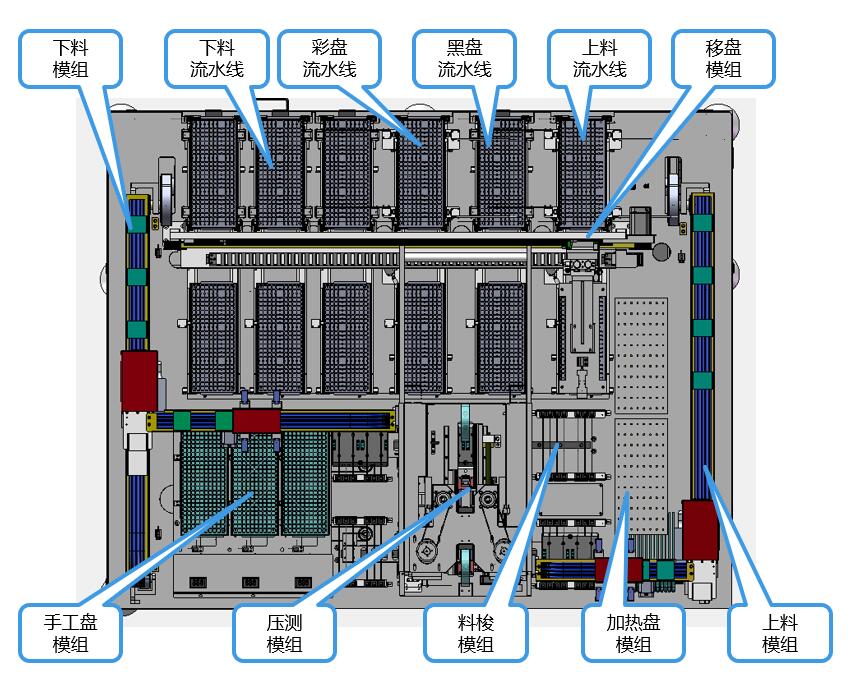

1、Divided into 11 major modules and 4 functional areas: loading, unloading, and conveyor zones;

2、Compact module layout saves installation space;

3、Self-developed system enables customization of various hardware and software functions;

4、Optional dual-temperature heating test system with advanced Socket Heat functionality;

5、Software can be custom-developed for customers: automatic height calibration and pressure setting, auto feeding test & manual test, supports dual-station/single-station testing, compatible with different Kit types, supports alarm options for shuttle warping, vibration, flying shuttle, feeding errors, chip drop re-pickup, and skip-module operation functions.

Testing and Sorting Explanation

Packaging and Testing Stage Inspection

Divided into Wafer Probe Testing (CP) before packaging and Final Test (FT) after packaging, primarily focusing on electrical performance testing.

Testing Equipment

Mainly divided into custom equipment and standard equipment. Standard equipment includes: Logic IC Test System, Memory IC Test System, SoC Test System, Analog/Mixed-Signal IC Test System, and RF IC Test System.

Testing Content

Testing content includes Contact/Continuity Test (open/short test), DC parameter testing, AC timing test, digital functional testing, and mixed-signal testing.

Evaluation Criteria

Mainly includes test function modules, test accuracy, response speed, application customization, and test data storage, acquisition, and analysis. Core technologies lie in functional integration, accuracy, speed, and scalability.

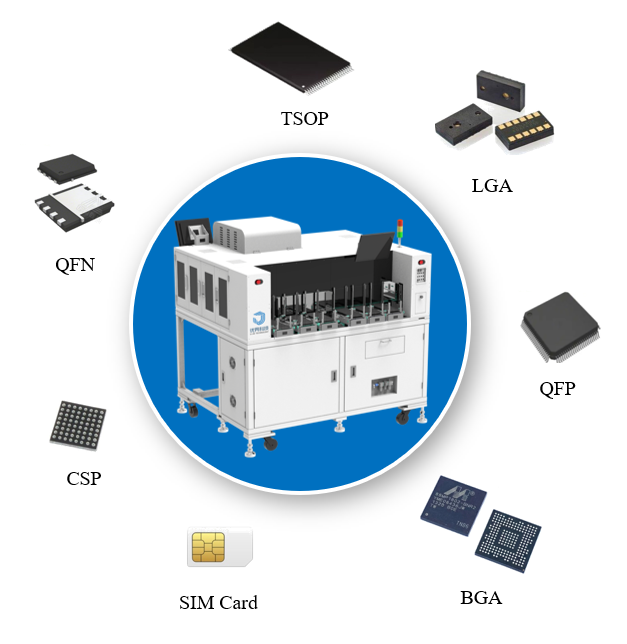

Chip size: Package size compatible from 3×3 mm to 40×40 mm

Package types: Suitable for post-packaged chips such as TSOP, QFN, QFP, SIM Card, LGA, BGA, CSP, etc.

Test content: DC parameter testing, functional testing, AC parameter testing, ADC and DAC testing, etc.

| Model Number | FT400-N/H | FT800-N/H |

|---|---|---|

封装尺寸Package Size | From 3 *3 To 40*40mm | |

Contact Force | 90kgf | 160kgf/240Kgf(可选) |

Pick up Head | 2*2,1*4(4 Site) | 2*4(8 Site) |

UPH | 8.5K(Base on 1*4,14*35Tray) | 11K(Base on 2*4,16*39Tray) |

Index Time | ≤0.38SContact Force≤90kgf) | ≤0.4S(Contact Force≤90kgf) |

≤0.5S(Contact Force≤160kgf) | ||

Jam Rate | ≤1/10000 | |

Tray Specification | JEDEC标准(行业通用标准) | |

Physical Bin Sorting | 自动盘*3,手工盘*3 | |

Communication Interface | TTL,GPIB,RS232,TCP/IP | |

Temperature Control Range (Optional) | ﹢50℃ to 100℃±2℃ | |

Dimensions & Weight | 1780(L)*1420(W)*1940(H) 不含报警灯,重量 950kg | 1880(L)*1420(W)*1940(H) 不含报警灯,重量 1000kg |

备注:设备参数若有修改恕不另行通知

—————————————————————————————————————————————————————————————————————————————————————

Hello, due to the confidentiality agreements signed for the detailed technical information of some commercial cases, it cannot be displayed online! If you need to obtain a customized solution, please contact us via mobile phone & WeChat: 181-2451-5629