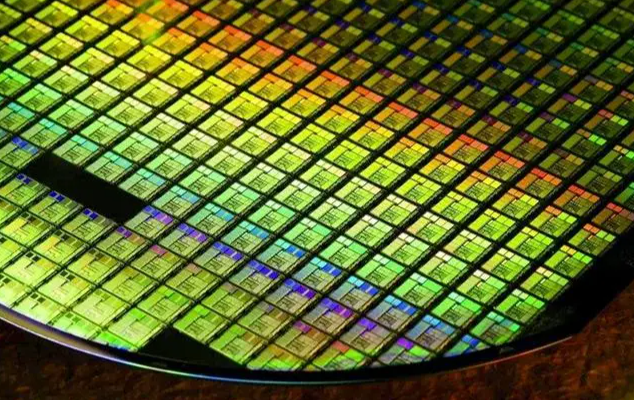

We know that wafers are round, but the chips made from them are square. This is primarily due to considerations of wafer utilization during chip manufacturing, ease of cutting, and the fact that a square shape makes routing (wiring) more convenient.

Why aren't chips round?

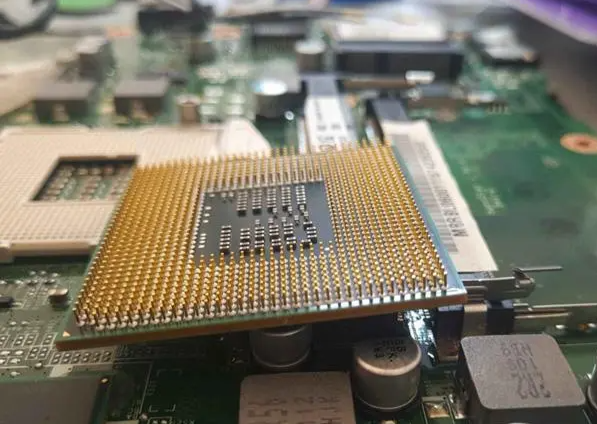

The basic material for chips is monocrystalline silicon. First, the monocrystalline silicon is processed into a circular wafer. Then, through precision manufacturing processes such as photolithography and etching, the wafer is intricately patterned and finally cut into hundreds or even thousands of individual chips.

In both computers and mobile phones, chips are mostly made square. They are designed this way instead of round for several reasons:

Circular chips would result in significant waste of material during the wafer cutting process. By making chips rectangular (which includes squares), the waste of raw material can be minimized.

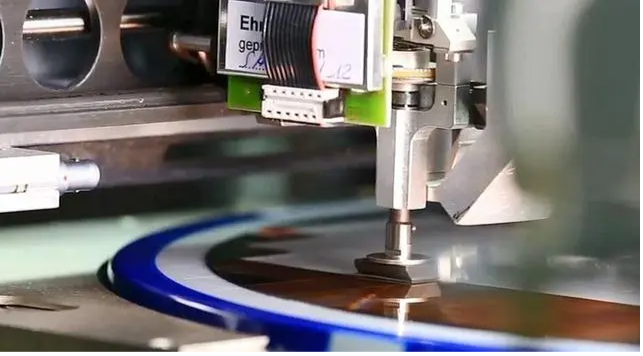

Chips are products of extremely high precision. When cutting wafers, straight cuts are the easiest to execute. Cutting along a curve requires much higher demands on the cutting tools, and given that the crystal nucleus of monocrystalline silicon has its own directional properties, curved cuts could easily damage the edges of the chips.

Rectangular chips are easier to position during wiring and installation. If they were circular, due to the rotational symmetry of a circle at any angle, even a slight angular deviation during wiring and installation could lead to errors.

Electronic products have a high degree of integration, and circular chips are not conducive to the overall layout of circuit boards.

Of course, aside from squares, equilateral triangles and regular hexagons could also allow for straight-line cutting without material waste. However, chip research, design, and manufacturing have evolved over decades of technological iteration, ultimately converging on the square as the optimal shape.

If chips are square, then why are wafers round?

The melting point of silicon is 1,410°C. The monocrystalline silicon used in chips requires extremely high purity. Silicon with 99.9999% purity is suitable for solar photovoltaic panels, but still far from meeting the requirements for chips. The purity of monocrystalline silicon for chips must be at least 99.999999%. Although some domestic companies in China are capable of producing chip-grade monocrystalline silicon, their output still cannot meet domestic demand, and a significant portion must be imported.

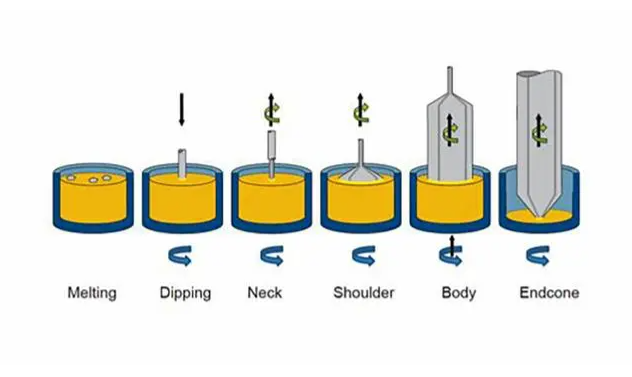

High-purity monocrystalline silicon is manufactured using the Czochralski method (also known as the pulling method). This process involves placing polycrystalline silicon into a quartz crucible and melting it. The temperature is then maintained at around 1,500°C. A small seed crystal is dipped into the molten silicon and rotated at a constant speed, while the crucible rotates in the opposite direction. The seed crystal is slowly pulled upward, causing the molten silicon to solidify and grow along the seed. This results in a cylindrical ingot of silicon, known as a monocrystalline silicon ingot, which can reach diameters of up to 30 centimeters and lengths of up to 1 meter.

We then slice the silicon ingot into thin wafers, resulting in the circular shape of the wafer. Although using circular wafers does lead to some edge material waste, the wafer's size is much larger than that of an individual chip—each wafer can produce hundreds or even thousands of chips. Therefore, the amount of wasted edge material is considered acceptable.