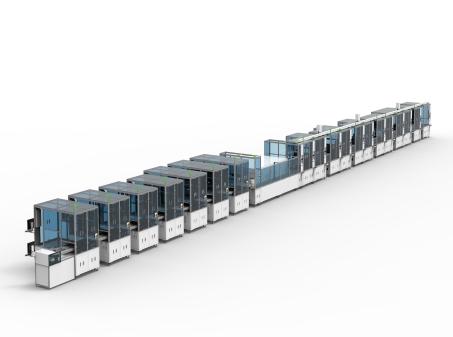

Production Line Introduction

1、Automatically performs loading/unloading, assembly, magnetization, potting, inline curing, aging, and testing processes for various relay products;

2、All materials are loaded/unloaded by material carts (upgradable to AGV automated loading/unloading in the future);

3、Utilizes multi-gripper robots for loading and assembly, adaptable for co-production of multiple types of materials;

4、Fully automated line requiring only 2 operators for loading, saving up to 40 laborers.

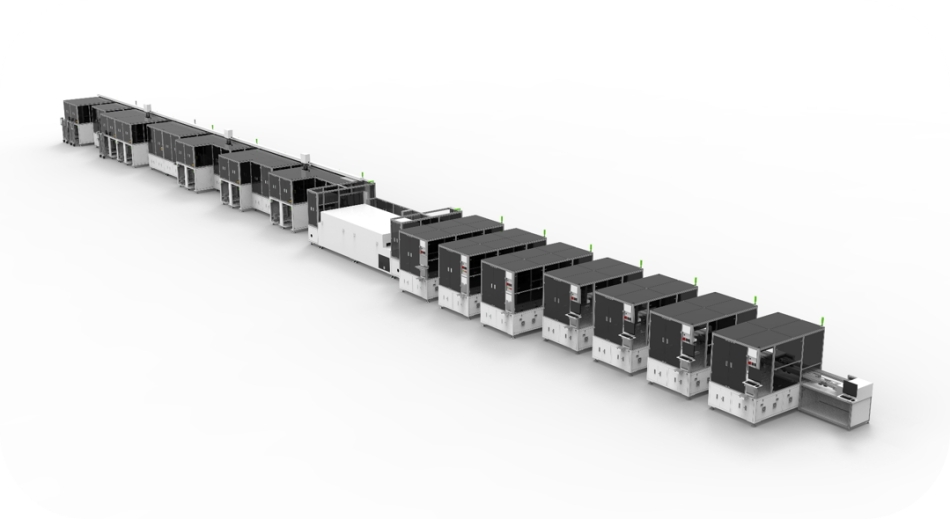

Highlights Introduction

1、Real-time monitoring of production line operation, with data network sharing to support production planning and decision-making;

2、Flexible compatibility with manufacturing requirements for multiple product models, reducing line adjustment and downtime;

3、Achieves unmanned AGV automated loading/unloading, reducing manual operations and improving transportation efficiency and line stability;

4、Employs single-line cleanroom production and Class 10,000 purification technology to ensure environmental cleanliness during product manufacturing;

5、Equipped with a real-time dust monitoring system for timely detection and alarms, ensuring the reliability of the production process and product quality.

| UPH | 10K/D |

| Precision | ±0.05mm |

| Dimensions (mm) | 9100*1800*1900 |

| Yield Rate | >98.0% |

—————————————————————————————————————————————————————————————————————————————————————

Hello, due to the confidentiality agreements signed for the detailed technical information of some commercial cases, it cannot be displayed online! If you need to obtain a customized solution, please contact us via mobile phone & WeChat: 181-2451-5629