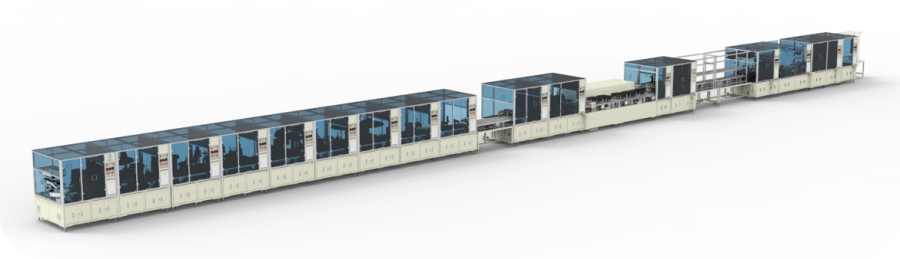

①. Fully automatic loading and unloading of relay products, using flexible vibrating feeders + vision systems + robotic feeding to ensure automatic handling, assembly, and terminal riveting for irregular components;

②. Uses clean sand belts for automatic removal of terminal debris, dispensing, inline curing, aging, simulated rotational testing, laser marking, and other processes;

③. All materials are loaded and unloaded by material carts (upgradeable to AGV automated loading and unloading in the future);

④. Utilizes multi-gripper robots for loading and assembly, adaptable for co-production of multiple types of materials;

⑤. Fully automated line requiring only 2 operators for loading;

⑥. Labor savings: 30 people.

1、Contact tooling: Hard chrome plating HCr + mirror polishing, using wear-resistant and high-hardness materials such as SKD11 or higher;

2、Dust removal and debris elimination capability exceeds 90%, confirmed through shell inspection and filter paper analysis;

3、Motion module repeatability accuracy for controlling critical dimensions is within ±0.01mm;

4、Repeatability accuracy of tolerance for silver point and core riveting process is controlled within ±0.03mm;

5、Compatible with multiple product models, enabling flexible production;

| UPH | 40K/D |

| Precision | ±0.05mm |

| Dimensions (mm) | 4100*1600*1900 |

| Yield Rate | >98.0% |

Note: Specifications are subject to change without prior notice

—————————————————————————————————————————————————————————————————————————————————————

Hello, due to the confidentiality agreements signed for the detailed technical information of some commercial cases, it cannot be displayed online! If you need to obtain a customized solution, please contact us via mobile phone & WeChat: 181-2451-5629